Agile or Lean or Both

Having completed the year Lecturing to undergraduates, at Wolverhampton University, its time to reflex.

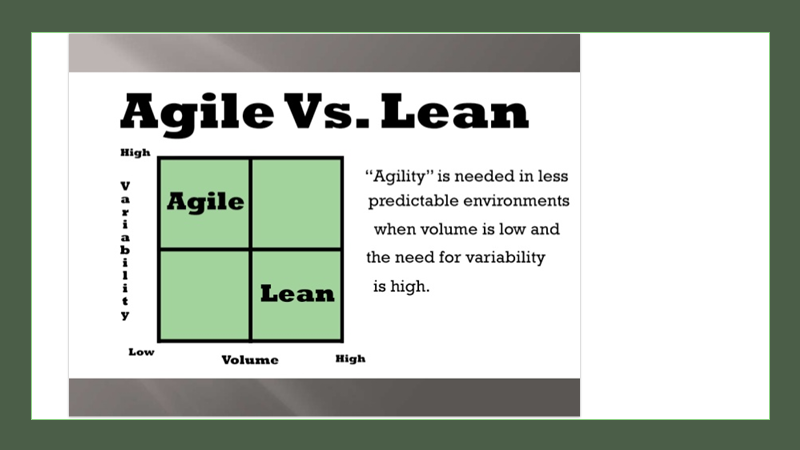

Lean or Agile or, this new term Lagile. Which to choose. Why bother at all.

I posed the question, if you were selling a product and making over 80% profit would you bother with lean or agile?

What is the business benefit? Why would we bother? what is the business imperative? where is the real benefit (minus the investment) in £ or $ or € DON’T JUST DO IT ‘CAUSE IT SOUNDS GOOD.

Clearly, we must think of lean / agile manufacturing in the business context. That all actions for improvement MUST have tangible / measurable benefits. There is no point in pouring £ks in to refining a process of a product or service that no one wants.

Many text book examples refer to repetitive processes, medium to high volume. So how do we manage Lean / Agile in bespoke Engineering?

All good questions :